The global gas delivery system for wafer fab equipment market encompasses a range of systems designed to efficiently supply and control gases crucial for semiconductor manufacturing in wafer fabrication facilities. These systems play a pivotal role in maintaining the stringent atmospheric conditions required for semiconductor production. They ensure the precise delivery of gases such as nitrogen, argon, and specialty gases to various stages of the fabrication process, contributing to optimal equipment performance and high-quality semiconductor output.

Access Full Report @ https://databridgemarketresearch.com/reports/global-gas-delivery-system-for-wafer-fab-equipment-market

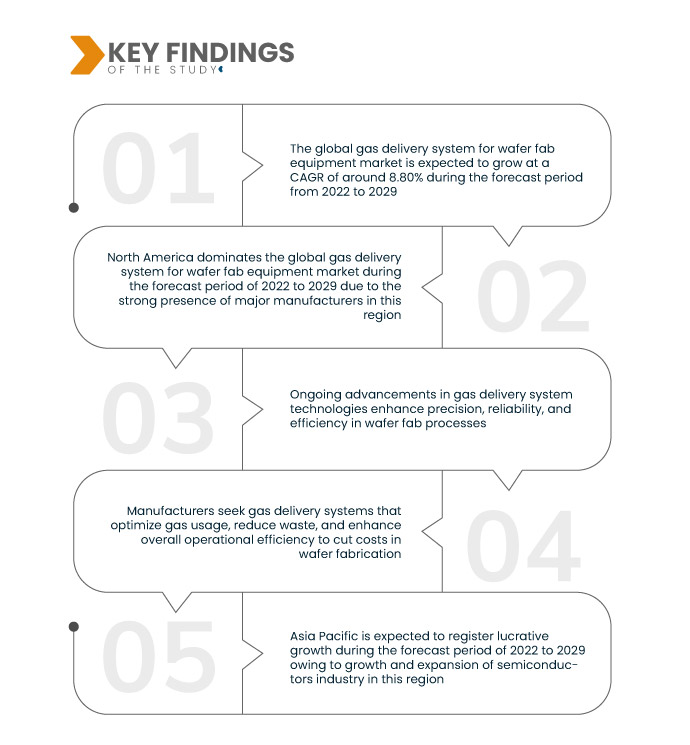

Data Bridge Market Research analyses that the Global Gas Delivery System for Wafer Fab Equipment Market is expected to grow at a CAGR of 8.80% for the forecast period of 2022-2029. The push for smaller and more powerful electronic devices demands precise gas control in wafer fabs, driving the uptake of advanced gas delivery systems to meet the exacting requirements of miniaturization trends.

Key Findings of the Study

Global demand for electronics is expected to drive the market's growth rate

Rising global demand for electronic devices propels the expansion of wafer fab capacities. This surge in production requirements drives the market for gas delivery systems, essential for maintaining optimal conditions in semiconductor manufacturing. As electronics permeate various industries, the necessity for reliable and efficient gas delivery systems grows, ensuring the scalability of wafer fabrication facilities to meet the increasing global appetite for advanced electronic components and devices.

Report Scope and Market Segmentation

Report Metric

|

Details

|

Forecast Period

|

2022 to 2029

|

Base Year

|

2021

|

Historic Years

|

2020 (Customizable to 2014-2019)

|

Segments Covered

|

Bulk Gas Type (Atmospheric Gases, Hydrogen, Helium and Acetylene), Type (Semi-Automatic Switchover Systems, Fully Automatic Programmable Switchover Systems and Single Station Systems), Component (Gas Cylinders, Manifolds, Gas Cabinets, Switchovers, Protocol Stations and Changeovers), Specialty Gases Type (Ammonia (NH3), Hydrogen Chloride (HCL), Tungsten Hexafluoride (WF6), Nitrogen Trifluoride (NF3), Nitrous Oxide (N2O), Disilane (SI2H6), Germane (GEH4) and High purity Carbon Dioxide (CO2))

|

Countries Covered

|

(U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel and Rest of Middle East and Africa)

|

Market Players Covered

|

Linde plc (U.K.), Messer SE & Co. KGaA (Germany), GCE Group (Sweden), CVD Equipment Corporation (U.S.), Applied Energy Systems, Inc. (U.S.), Indiana Oxygen (U.S.), Critical Process Systems Group (U.S.), INTEGA GmbH (Germany), Powerblanket (U.S.), IEEE (Institute of Electrical and Electronics Engineers) (U.S.), Kelington Group Berhad (Malaysia), Critical Systems, Inc. (U.S.), Ichor Systems (U.S.), MATHESON TRI-GAS, INC. (U.S.), Praxair Technology, Inc. (Now part of Linde plc) (U.S.), Air Products Inc. (U.S.), Iwatani Corporation (Japan), BASF SE (Germany), Air Liquide (France), Colfax Corporation (U.S.) among others

|

Data Points Covered in the Report

|

In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically represented company-wise production and capacity, network layouts of distributors and partners, detailed and updated price trend analysis and deficit analysis of supply chain and demand.

|

Segment Analysis:

The global gas delivery system for the wafer fab equipment market is segmented on the basis of bulk gas type, type, component, and specialty gas type.

- On the basis of bulk gas type, the global gas delivery system for wafer fab equipment market is segmented into atmospheric gases, hydrogen, helium, and acetylene

- On the basis of type, the global gas delivery system for wafer fab equipment market is segmented into semi-automatic switchover systems, fully automatic programmable switchover systems, and single station systems

- On the basis of component, the global gas delivery system for wafer fab equipment market is segmented into gas cylinders, manifolds, gas cabinets, switchovers, protocol stations, and changeovers

- On the basis of specialty gases type, the global gas delivery system for wafer fab equipment market is segmented into ammonia (NH3), hydrogen chloride (HCL), tungsten hexafluoride (WF6), nitrogen trifluoride (NF3), nitrous oxide (N2O), disilane (SI2H6), germane (GEH4) and high Purity carbon dioxide (CO2)

Major Players

Data Bridge Market Research recognizes the following companies as the major global gas delivery system for wafer fab equipment market players in global gas delivery system for wafer fab equipment market are Ichor Systems (U.S.), MATHESON TRI-GAS, INC. (U.S.), Praxair Technology, Inc. (Now part of Linde plc) (U.S.), Air Products Inc. (U.S.), Iwatani Corporation (Japan), BASF SE (Germany), Air Liquide (France), Colfax Corporation (U.S.)

Market Developments

- In March 2022, SK Siltron Co. revealed a substantial investment of KRW 1.05 trillion over three years to expand its 300 mm wafer facilities in Gumi National Industrial Complex 3. The expansion project, commencing in 2022, aims to enable mass production by 2024, solidifying the company's commitment to semiconductor manufacturing growth

- In February 2022, UK university research spin-out Intrinsic Semiconductor Technology launched ReRAM technology. This innovation enables the manufacturing of non-volatile memory on CMOS wafers alongside microcontrollers. The integration eliminates the need for separate NAND chips, offering the potential for integrated SRAM-speed non-volatile memory in a single chi

- In January 2022, GlobalWafers Co., a prominent silicon wafer supplier, expanded its capacity by incorporating approximately 20,000 advanced 12-inch wafers monthly from local fabs. The expansion is anticipated to increase capacity by 10-15% across plants in South Korea, Japan, Taiwan, and Italy, addressing robust global demand for silicon wafers in the semiconductor industry

- In November 2021, Texas Instruments Incorporated revealed plans for new 300-millimeter semiconductor wafer fabrication plants in Sherman, Texas. With a focus on industrial and automotive applications, the North Texas location could accommodate up to four fabs over time, showcasing the company's commitment to advancing semiconductor development. The initial two fabs are anticipated to be operational by 2022

Regional Analysis

Geographically, the countries covered in the global gas delivery system for wafer fab equipment market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

As per Data Bridge Market Research analysis:

North America is the dominant region in the global gas delivery system for wafer fab equipment market during the forecast period 2022-2029

North America dominates the global gas delivery system for wafer fab equipment market, maintaining its stronghold throughout the forecast period. This dominance is attributed to the region's robust industry presence, with major manufacturers contributing to its flourishing trend. The concentration of key industry players in North America ensures sustained growth, supported by their technological expertise and market influence. The region remains pivotal, steering the trajectory of the gas delivery system market for wafer fab equipment.

Asia-Pacific is estimated to be the fastest growing region in the global gas delivery system for wafer fab equipment market during the forecast period 2022-2029

Asia-Pacific is expected to dominate the global gas delivery system for wafer fab equipment market, projecting substantial gains and the highest CAGR. This dominance is attributed to the region's growing semiconductor industry, marked by significant growth and expansion. As the demand for semiconductors continues to rise in Asia-Pacific, the need for advanced gas delivery systems follows suit, positioning the region as a key driver in the market's growth trajectory during the forecast period.

For more detailed information about the global gas delivery system for wafer fab equipment market report, click here – https://www.databridgemarketresearch.com/reports/global-gas-delivery-system-for-wafer-fab-equipment-market