Global Aerospace Forging Market

Market Size in USD Billion

CAGR :

%

USD

32.54 Billion

USD

59.51 Billion

2021

2029

USD

32.54 Billion

USD

59.51 Billion

2021

2029

| 2022 –2029 | |

| USD 32.54 Billion | |

| USD 59.51 Billion | |

|

|

|

|

Market Analysis and Size

The market has witnessed increasing demand for a high strength-to-weight ratio and robust aircraft structural dependability over the recent years. The growing demand for forged components made from various alloys in aircraft is expected to drive the market. Moreover, the rising air passenger traffic, major players in the commercial aviation industry are expected to see an increase in the number of aircraft deliveries, boosting the overall expansion of market.

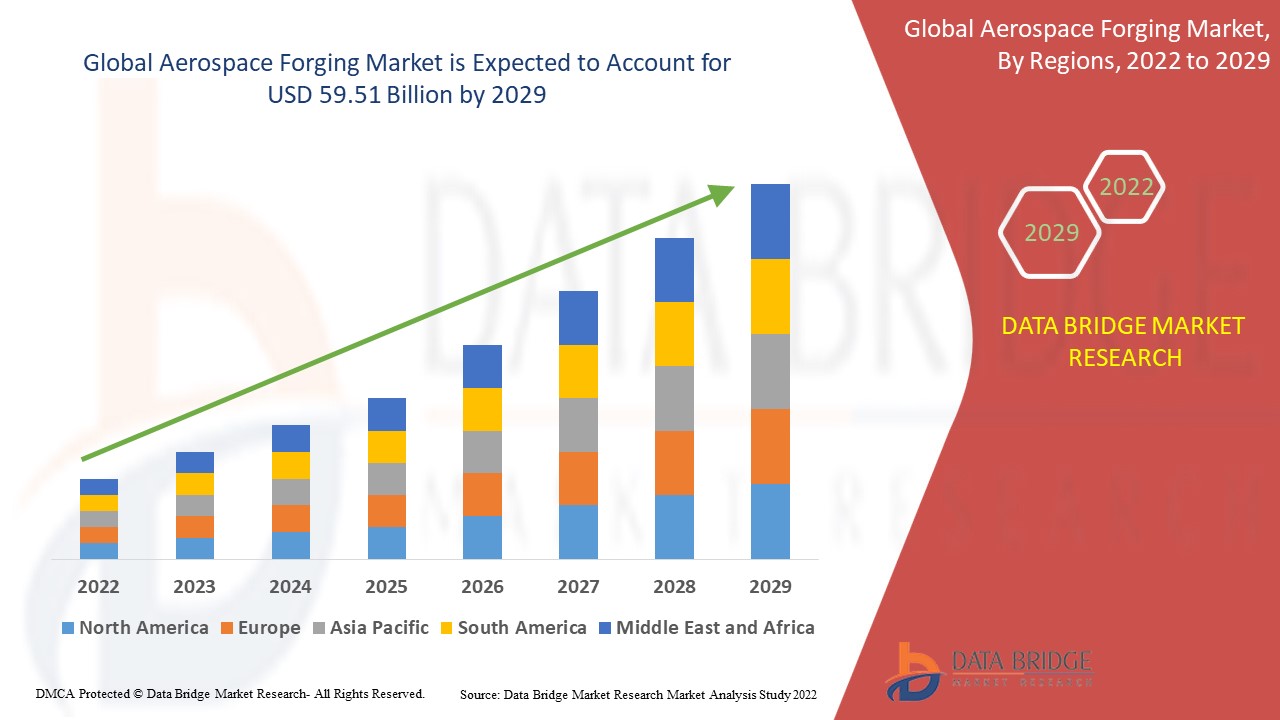

Global Aerospace Forging Market was valued at USD 32.54 billion in 2021 and is expected to reach USD 59.51 billion by 2029, registering a CAGR of 7.61% during the forecast period of 2022-2029. In addition to the market insights such as market value, growth rate, market segments, geographical coverage, market players, and market scenario, the market report curated by the Data Bridge Market Research team also includes in-depth expert analysis, import/export analysis, pricing analysis, production consumption analysis, and climate chain scenario.

Report Scope and Market Segmentation

|

Report Metric |

Details |

|

Forecast Period |

2022 to 2029 |

|

Base Year |

2021 |

|

Historic Years |

2020 (Customizable to 2014 - 2019) |

|

Quantitative Units |

Revenue in USD Billion, Volumes in Units, Pricing in USD |

|

Segments Covered |

By Material Type (Titanium, Stainless Steel, Aluminum Alloy, Others), Aircraft Type (Fixed Wing, Rotary Wing), Application (Rotors, Turbine Disc, Shafts, Fan Case, Others), Product Type (Closed Die, Open Die, Rolled Rings), End-Use (Commercial, Military, Others) |

|

Countries Covered |

U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa |

|

Market Players Covered |

Arconic (U.S.), ATI (Canada), Bharat Forge (India), ELLWOOD Group Inc (U.S.), JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LTD (China), Precision Castparts Corp (U.S.), LARSEN & TOUBRO LIMITED (India), Scot Forge Company (U.S.) Pacific Forge Incorporated (U.S.), Somers Forge (U.K.), eramet (France), VSMPO-AVISMA Corporation (Russia), ALL METALS & FORGE GROUP (U.S.), Consolidated Industries, Inc (U.S.), Farinia (U.S.), Mettis Group (U.S.) |

|

Market Opportunities |

|

Market Definition

Aerospace forging is basically a manufacturing process that involves shaping metal using localized compressive forces. Alloys are blended with various components in the form of powder during the forging process. The pieces are then cut together to form a solid part. This method produces long-lasting and lightweight components for use in aircraft.

Aerospace forging Market Dynamics

This section deals with understanding the market drivers, advantages, opportunities, restraints and challenges. All of this is discussed in detail as below:

Drivers

- High Demand Across Aerospace Sector

The growing demand for forged components made from various alloys in aircraft is expected to drive the market. Furthermore, rising commercial aircraft production, as well as rising demand for aircraft parts such as engine parts, landing gears, machined parts, and turbines, is expected to drive market growth over the forecast period. The demand for aerospace forged elements is expected to rise as the number of military-grade aero planes such as helicopters, specialty fighters, and jets increases to improve air defense. Therefore, the increased applications across aerospace sector will further accelerate the market growth.

Factors such as the increase in international and domestic travel, as well as the well-established aircraft sector, are propelling the market's growth. Additionally, the expanding tourism sector as a result of an increase in foreign tourists globally has propelled the aviation business, thereby increasing the demand for aerospace forging.

Opportunities

- Advancements and Research and Development Activities

Furthermore, various developments such as development of 3rd generation of Al-Li alloys and advancements by the market players in distinctive alloys further enhance the applications of product, extend profitable opportunities to the market players in the forecast period of 2022 to 2029. Additionally, the growing research and development activities further promote the usage of aerospace forging will further expand the future growth of the aerospace forging market.

Restraints/Challenges

- High Competition from Other Methods

The increasing competition from other production method such as casting along with cyclic changes in commercial aerospace which are estimated to act as market restraint factor for the growth of the aerospace forging market in the above mentioned projected timeframe.

- Stringent Government Regulations

Also, the presence of various strict government regulations for the aerospace market due to the increasing concern regarding environmental hazards will prove to be a demerit for the aerospace forging market. These regulations associated with environment further pose as a challenge for the aerospace forging market growth rate.

This aerospace forging market report provides details of new recent developments, trade regulations, import-export analysis, production analysis, value chain optimization, market share, impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, strategic market growth analysis, market size, category market growths, application niches and dominance, product approvals, product launches, geographic expansions, technological innovations in the market. To gain more info on the aerospace forging market contact Data Bridge Market Research for an Analyst Brief, our team will help you take an informed market decision to achieve market growth.

COVID-19 Impact on Aerospace Forging Market

The recent outbreak of coronavirus had a negative impact on the aerospace forging market The pandemic has had a significant impact on the world's major economies, including China and the United States, and it is unclear when normalcy will be restored. The aerospace forging process is inextricably linked to the manufacturing process, and the pandemic is clearly having a negative impact on the industry. Aircraft manufacturers are concerned about their cash flow and liquidity because the industry is highly capital intensive, and they expect to spend less in the near future. The supply chain disruption caused by the lockdown is expected to have an impact on the companies' future growth. Due to a lack of laborers, aircraft manufacturing has ceased completely, and thus demand for spare parts has decreased significantly. Revenue is not being generated for the companies as a result of the ongoing pandemic, which will result in significant losses throughout the year. Moreover, the revenue generation of aerospace forging companies has suffered a significant financial loss.

To resurrect the market, businesses must deal on a high margin. Although, the market is estimated to recover due to the relaxation of enforced lockdowns but aerospace forging production will be more agile. The situation in the military aviation market is slightly better because project budgets have already been allocated, which will drive market understudy to some extent, but industry experts are unsure whether this trend will continue in the long term.

Global Aerospace Forging Market Scope

The aerospace forging market is segmented on the basis of material type, aircraft type, application, product type and product type. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Material Type

- Titanium

- Stainless Steel

- Aluminum Alloy

- Others

Aircraft Type

- Fixed Wing

- Rotary Wing

Application

- Rotors

- Turbine Disc

- Shafts

- Fan Case

- Others

Product Type

- Closed Die

- Open Die

- Rolled Rings

End-Use

- Commercial

- Military

- Others

Aerospace Forging Market Regional Analysis/Insights

The aerospace forging market is analyzed and market size insights and trends are provided by country, material type, aircraft type, application, product type and product type as referenced above.

The countries covered in the aerospace forging market report are U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, Israel, Egypt, South Africa, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

North America dominates the market in terms of market share and market revenue and will continue to flourish its dominance during the forecast period of 2022-2029. The market growth over this region is attributed to the increasing prevalence of various aerospace and component manufacturing companies within the region.

Asia-Pacific on the other hand, is estimated to show lucrative growth over the forecast period of 2022-2029, due to the surging levels of investment for the development of aviation infrastructure along with prevalence of domestic air transport in the region.

The country section of the report also provides individual market impacting factors and changes in market regulation that impact the current and future trends of the market. Data points like down-stream and upstream value chain analysis, technical trends and porter's five forces analysis, case studies are some of the pointers used to forecast the market scenario for individual countries. Also, the presence and availability of global brands and their challenges faced due to large or scarce competition from local and domestic brands, impact of domestic tariffs and trade routes are considered while providing forecast analysis of the country data.

Competitive Landscape and Aerospace Forging Market Share Analysis

The aerospace forging market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to aerospace forging market.

Some of the major players operating in the aerospace forging market are

- Arconic (U.S.)

- ATI (Canada)

- Bharat Forge (India)

- ELLWOOD Group Inc (U.S.)

- JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LTD (China)

- Precision Castparts Corp (U.S.)

- LARSEN & TOUBRO LIMITED (India)

- Scot Forge Company (U.S.)

- Pacific Forge Incorporated (U.S.)

- Somers Forge (U.K.)

- Eramet (France)

- VSMPO-AVISMA Corporation (Russia)

- ALL METALS & FORGE GROUP (U.S.)

- Consolidated Industries, Inc (U.S.)

- Farinia (U.S.)

- Mettis Group (U.S.)

SKU-

Get online access to the report on the World's First Market Intelligence Cloud

- Interactive Data Analysis Dashboard

- Company Analysis Dashboard for high growth potential opportunities

- Research Analyst Access for customization & queries

- Competitor Analysis with Interactive dashboard

- Latest News, Updates & Trend analysis

- Harness the Power of Benchmark Analysis for Comprehensive Competitor Tracking

Table of Content

1 INTRODUCTION

1.1 OBJECTIVES OF THE STUDY

1.2 MARKET DEFINITION

1.3 OVERVIEW OF GLOBAL AEROSPACE FORGING MARKET

1.4 CURRENCY AND PRICING

1.5 LIMITATION

1.6 MARKETS COVERED

2 MARKET SEGMENTATION

2.1 KEY TAKEAWAYS

2.2 ARRIVING AT THE GLOBAL AEROSPACE FORGING MARKET SIZE

2.3 VENDOR POSITIONING GRID

2.4 MARKETS COVERED

2.5 GEOGRAPHIC SCOPE

2.6 YEARS CONSIDERED FOR THE STUDY

2.7 RESEARCH METHODOLOGY

2.8 TECHNOLOGY LIFE LINE CURVE

2.9 MULTIVARIATE MODELLING

2.1 PRIMARY INTERVIEWS WITH KEY OPINION LEADERS

2.11 DBMR MARKET POSITION GRID

2.12 MARKET APPLICATION COVERAGE GRID

2.13 DBMR MARKET CHALLENGE MATRIX

2.14 IMPORT AND EXPORT DATA

2.15 SECONDARY SOURCES

2.16 GLOBAL AEROSPACE FORGING MARKET: RESEARCH SNAPSHOT

2.17 ASSUMPTIONS

3 MARKET OVERVIEW

3.1 DRIVERS

3.2 RESTRAINTS

3.3 OPPORTUNITIES

3.4 CHALLENGES

4 EXECUTIVE SUMMARY

5 PREMIUM INSIGHTS

5.1 RAW MATERIAL COVERAGE

5.2 PRODUCTION CONSUMPTION ANALYSIS

5.3 IMPORT EXPORT SCENARIO

5.4 TECHNOLOGICAL ADVANCEMENT BY MANUFACTURERS

5.5 PORTER’S FIVE FORCES

5.6 VENDOR SELECTION CRITERIA

5.7 PESTEL ANALYSIS

5.8 REGULATION COVERAGE

5.8.1 PRODUCT CODES

5.8.2 CERTIFIED STANDARDS

5.8.3 SAFETY STANDARDS

5.8.3.1. MATERIAL HANDLING & STORAGE

5.8.3.2. TRANSPORT & PRECAUTIONS

5.8.3.3. HARAD IDENTIFICATION

6 PRICE INDEX

7 PRODUCTION CAPACITY OVERVIEW

8 SUPPLY CHAIN ANALYSIS

8.1 OVERVIEW

8.2 LOGISTIC COST SCENARIO

8.3 IMPORTANCE OF LOGISTICS SERVICE PROVIDERS

9 CLIMATE CHANGE SCENARIO

9.1 ENVIRONMENTAL CONCERNS

9.2 INDUSTRY RESPONSE

9.3 GOVERNMENT’S ROLE

9.4 ANALYST RECOMMENDATIONS

10 GLOBAL AEROSPACE FORGING MARKET, BY RAW MATERIAL, (2022-2031), (USD MILLION) (TONS)

10.1 OVERVIEW

10.2 STEEL

10.2.1 SS410

10.2.2 SS 310

10.2.3 SS 304

10.2.4 OTHERS

10.3 ALUMINUM

10.4 TITANIUM

10.5 NICKEL ALLOYS

10.6 OTHERS

11 GLOBAL AEROSPACE FORGING MARKET, BY PRODUCT, (2022-2031), (USD MILLION) (KILO TONS)

11.1 OVERVIEW

11.2 OPEN DIE FORGING

11.3 CLOSED DIE FORGING

11.4 SEAMLESS ROLLED RING FORGING

12 GLOBAL AEROSPACE FORGING MARKET, BY AIRCRAFT TYPE, (2022-2031), (USD MILLION)

12.1 OVERVIEW

12.2 FIXED WING

12.3 ROTARY WING

13 GLOBAL AEROSPACE FORGING MARKET, BY APPLICATION, (2022-2031), (USD MILLION)

13.1 OVERVIEW

13.2 SHAFTS

13.3 TURBINE DISCS

13.4 ROTORS

13.5 SEALS

13.6 DOOR FRAMES

13.7 FAN CASE

13.8 LANDING GEAR COMPONENTS

13.9 OTHERS

14 GLOBAL AEROSPACE FORGING MARKET, BY END-USE, (2022-2031), (USD MILLION)

14.1 OVERVIEW

14.2 PASSENGER

14.2.1 PASSENGER, BY CATEGORY

14.2.1.1. NARROW-BODY AIRCRAFT

14.2.1.2. WIDE-BODY AIRCRAFT

14.2.2 PASSENGER, BY RAW MATERIAL

14.2.2.1. STEEL

14.2.2.1.1. SS410

14.2.2.1.2. SS 310

14.2.2.1.3. SS 304

14.2.2.1.4. OTHERS

14.2.2.2. ALUMINUM

14.2.2.3. TITANIUM

14.2.2.4. NICKEL ALLOYS

14.2.2.5. OTHERS

14.2.3 PASSENGER, BY PRODUCT

14.2.3.1. OPEN DIE FORGING

14.2.3.2. CLOSED DIE FORGING

14.2.3.3. SEAMLESS ROLLED RING FORGING

14.3 CARGO

14.3.1 CARGO, BY RAW MATERIAL

14.3.1.1. STEEL

14.3.1.1.1. SS410

14.3.1.1.2. SS 310

14.3.1.1.3. SS 304

14.3.1.1.4. OTHERS

14.3.1.2. ALUMINUM

14.3.1.3. TITANIUM

14.3.1.4. NICKEL ALLOYS

14.3.1.5. OTHERS

14.3.2 CARGO, BY PRODUCT

14.3.2.1. OPEN DIE FORGING

14.3.2.2. CLOSED DIE FORGING

14.3.2.3. SEAMLESS ROLLED RING FORGING

14.4 DEFENSE

14.4.1 DEFENSE, BY CATEGORY

14.4.1.1. FIGHTER JETS

14.4.1.2. TRANSPORT AIRCRAFT

14.4.2 DEFENSE, BY RAW MATERIAL

14.4.2.1. STEEL

14.4.2.1.1. SS410

14.4.2.1.2. SS 310

14.4.2.1.3. SS 304

14.4.2.1.4. OTHERS

14.4.2.2. ALUMINUM

14.4.2.3. TITANIUM

14.4.2.4. NICKEL ALLOYS

14.4.2.5. OTHERS

14.4.3 DEFENSE, BY PRODUCT

14.4.3.1. OPEN DIE FORGING

14.4.3.2. CLOSED DIE FORGING

14.4.3.3. SEAMLESS ROLLED RING FORGING

14.5 HELICOPTERS

14.5.1 HELICOPTERS, BY CATEGORY

14.5.1.1. MILITARY HELICOPTERS

14.5.1.2. CIVILIAN HELICOPTERS

14.5.2 HELICOPTERS, BY RAW MATERIAL

14.5.2.1. STEEL

14.5.2.1.1. SS410

14.5.2.1.2. SS 310

14.5.2.1.3. SS 304

14.5.2.1.4. OTHERS

14.5.2.2. ALUMINUM

14.5.2.3. TITANIUM

14.5.2.4. NICKEL ALLOYS

14.5.2.5. OTHERS

14.5.3 HELICOPTERS, BY PRODUCT

14.5.3.1. OPEN DIE FORGING

14.5.3.2. CLOSED DIE FORGING

14.5.3.3. SEAMLESS ROLLED RING FORGING

14.6 OTHERS

15 GLOBAL AEROSPACE FORGING MARKET, BY GEOGRAPHY, (2022-2031), (USD MILLION)

Global AEROSPACE FORGING market, (ALL SEGMENTATION PROVIDED ABOVE IS REPRESENTED IN THIS CHAPTER BY COUNTRY)

15.1 NORTH AMERICA

15.1.1 U.S.

15.1.2 CANADA

15.1.3 MEXICO

15.2 EUROPE

15.2.1 GERMANY

15.2.2 U.K.

15.2.3 ITALY

15.2.4 FRANCE

15.2.5 SPAIN

15.2.6 RUSSIA

15.2.7 SWITZERLAND

15.2.8 TURKEY

15.2.9 BELGIUM

15.2.10 NETHERLANDS

15.2.11 LUXEMBURG

15.2.12 REST OF EUROPE

15.3 ASIA-PACIFIC

15.3.1 JAPAN

15.3.2 CHINA

15.3.3 SOUTH KOREA

15.3.4 INDIA

15.3.5 SINGAPORE

15.3.6 THAILAND

15.3.7 INDONESIA

15.3.8 MALAYSIA

15.3.9 PHILIPPINES

15.3.10 AUSTRALIA & NEW ZEALAND

15.3.11 REST OF ASIA-PACIFIC

15.4 SOUTH AMERICA

15.4.1 BRAZIL

15.4.2 ARGENTINA

15.4.3 REST OF SOUTH AMERICA

15.5 MIDDLE EAST AND AFRICA

15.5.1 SOUTH AFRICA

15.5.2 EGYPT

15.5.3 SAUDI ARABIA

15.5.4 UNITED ARAB EMIRATES

15.5.5 ISRAEL

15.5.6 REST OF MIDDLE EAST AND AFRICA

16 GLOBAL AEROSPACE FORGING MARKET, COMPANY LANDSCAPE

16.1 COMPANY SHARE ANALYSIS: GLOBAL

16.2 COMPANY SHARE ANALYSIS: NORTH AMERICA

16.3 COMPANY SHARE ANALYSIS: EUROPE

16.4 COMPANY SHARE ANALYSIS: ASIA-PACIFIC

16.5 MERGERS AND ACQUISITIONS

16.6 NEW PRODUCT DEVELOPMENT AND APPROVALS

16.7 EXPANSIONS

16.8 PARTNERSHIP AND OTHER STRATEGIC DEVELOPMENTS

17 SWOT AND DATA BRIDGE MARKET RESEARCH ANALYSIS

18 GLOBAL AEROSPACE FORGING MARKET- COMPANY PROFILE

18.1 ATI

18.1.1 COMPANY SNAPSHOT

18.1.2 REVENUE ANALYSIS

18.1.3 PRODUCT PORTFOLIO

18.1.4 RECENT UPDATES

18.2 ELLWOOD GROUP INC.

18.2.1 COMPANY SNAPSHOT

18.2.2 REVENUE ANALYSIS

18.2.3 PRODUCT PORTFOLIO

18.2.4 RECENT UPDATES

18.3 SCOT FORGE

18.3.1 COMPANY SNAPSHOT

18.3.2 REVENUE ANALYSIS

18.3.3 PRODUCT PORTFOLIO

18.3.4 RECENT UPDATES

18.4 ARCONIC

18.4.1 COMPANY SNAPSHOT

18.4.2 REVENUE ANALYSIS

18.4.3 PRODUCT PORTFOLIO

18.4.4 RECENT UPDATES

18.5 LARSEN & TURBO LIMITED

18.5.1 COMPANY SNAPSHOT

18.5.2 REVENUE ANALYSIS

18.5.3 PRODUCT PORTFOLIO

18.5.4 RECENT UPDATES

18.6 SOMERS FORGE LTD.

18.6.1 COMPANY SNAPSHOT

18.6.2 REVENUE ANALYSIS

18.6.3 PRODUCT PORTFOLIO

18.6.4 RECENT UPDATES

18.7 AUBERT & DUVAL

18.7.1 COMPANY SNAPSHOT

18.7.2 REVENUE ANALYSIS

18.7.3 PRODUCT PORTFOLIO

18.7.4 RECENT UPDATES

18.8 PACIFIC FORGE INCORPORATED

18.8.1 COMPANY SNAPSHOT

18.8.2 REVENUE ANALYSIS

18.8.3 PRODUCT PORTFOLIO

18.8.4 RECENT UPDATES

18.9 BHARAT FORGE LTD.

18.9.1 COMPANY SNAPSHOT

18.9.2 REVENUE ANALYSIS

18.9.3 PRODUCT PORTFOLIO

18.9.4 RECENT UPDATES

18.1 ALL METALS & FORGE GROUP

18.10.1 COMPANY SNAPSHOT

18.10.2 REVENUE ANALYSIS

18.10.3 PRODUCT PORTFOLIO

18.10.4 RECENT UPDATES

18.11 FARINIA GROUP

18.11.1 COMPANY SNAPSHOT

18.11.2 REVENUE ANALYSIS

18.11.3 PRODUCT PORTFOLIO

18.11.4 RECENT UPDATES

18.12 PRECISION CASTPARTS CORP

18.12.1 COMPANY SNAPSHOT

18.12.2 REVENUE ANALYSIS

18.12.3 PRODUCT PORTFOLIO

18.12.4 RECENT UPDATES

18.13 METTIS AEROSPACE

18.13.1 COMPANY SNAPSHOT

18.13.2 REVENUE ANALYSIS

18.13.3 PRODUCT PORTFOLIO

18.13.4 RECENT UPDATES

18.14 JIANGYIN HENGRUN HEAVY INDUSTRIES CO., LT

18.14.1 COMPANY SNAPSHOT

18.14.2 REVENUE ANALYSIS

18.14.3 PRODUCT PORTFOLIO

18.14.4 RECENT UPDATES

18.15 UACJ CORPORATIONV

18.15.1 COMPANY SNAPSHOT

18.15.2 REVENUE ANALYSIS

18.15.3 PRODUCT PORTFOLIO

18.15.4 RECENT UPDATES

18.16 CONSOLIDATED INDUSTRIES INC.

18.16.1 COMPANY SNAPSHOT

18.16.2 REVENUE ANALYSIS

18.16.3 PRODUCT PORTFOLIO

18.16.4 RECENT UPDATES

18.17 FOUNTAINTOWN FORGE INC.

18.17.1 COMPANY SNAPSHOT

18.17.2 REVENUE ANALYSIS

18.17.3 PRODUCT PORTFOLIO

18.17.4 RECENT UPDATES

18.18 VICTORIA DROP FORGINGS CO. LTD.

18.18.1 COMPANY SNAPSHOT

18.18.2 REVENUE ANALYSIS

18.18.3 PRODUCT PORTFOLIO

18.18.4 RECENT UPDATES

NOTE: THE COMPANIES PROFILED IS NOT EXHAUSTIVE LIST AND IS AS PER OUR PREVIOUS CLIENT REQUIREMENT. WE PROFILE MORE THAN 100 COMPANIES IN OUR STUDY AND HENCE THE LIST OF COMPANIES CAN BE MODIFIED OR REPLACED ON REQUEST

19 RELATED REPORTS

20 QUESTIONNAIRE

21 CONCLUSION

22 ABOUT DATA BRIDGE MARKET RESEARCH

Global Aerospace Forging Market, Supply Chain Analysis and Ecosystem Framework

To support market growth and help clients navigate the impact of geopolitical shifts, DBMR has integrated in-depth supply chain analysis into its Global Aerospace Forging Market research reports. This addition empowers clients to respond effectively to global changes affecting their industries. The supply chain analysis section includes detailed insights such as Global Aerospace Forging Market consumption and production by country, price trend analysis, the impact of tariffs and geopolitical developments, and import and export trends by country and HSN code. It also highlights major suppliers with data on production capacity and company profiles, as well as key importers and exporters. In addition to research, DBMR offers specialized supply chain consulting services backed by over a decade of experience, providing solutions like supplier discovery, supplier risk assessment, price trend analysis, impact evaluation of inflation and trade route changes, and comprehensive market trend analysis.

Research Methodology

Data collection and base year analysis are done using data collection modules with large sample sizes. The stage includes obtaining market information or related data through various sources and strategies. It includes examining and planning all the data acquired from the past in advance. It likewise envelops the examination of information inconsistencies seen across different information sources. The market data is analysed and estimated using market statistical and coherent models. Also, market share analysis and key trend analysis are the major success factors in the market report. To know more, please request an analyst call or drop down your inquiry.

The key research methodology used by DBMR research team is data triangulation which involves data mining, analysis of the impact of data variables on the market and primary (industry expert) validation. Data models include Vendor Positioning Grid, Market Time Line Analysis, Market Overview and Guide, Company Positioning Grid, Patent Analysis, Pricing Analysis, Company Market Share Analysis, Standards of Measurement, Global versus Regional and Vendor Share Analysis. To know more about the research methodology, drop in an inquiry to speak to our industry experts.

Customization Available

Data Bridge Market Research is a leader in advanced formative research. We take pride in servicing our existing and new customers with data and analysis that match and suits their goal. The report can be customized to include price trend analysis of target brands understanding the market for additional countries (ask for the list of countries), clinical trial results data, literature review, refurbished market and product base analysis. Market analysis of target competitors can be analyzed from technology-based analysis to market portfolio strategies. We can add as many competitors that you require data about in the format and data style you are looking for. Our team of analysts can also provide you data in crude raw excel files pivot tables (Fact book) or can assist you in creating presentations from the data sets available in the report.